Ideally part designers should know that when it comes to aluminum grades 3003 and 5052 will bend 6061 will not.

Aluminum grade for sheet metal sharp bends.

This is done through the application of force on a workpiece.

In this post we ll explain it to you.

A simple metal folder suitable for making small metal boxes and chassis is also described.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

Highly formable and one of the best kinds of aluminum to bend.

That is it gets stronger and harder by working bending it.

This is generalizing of course as there are ways to form 6061.

The force must exceed the material s yield strength to achieve a plastic deformation.

Proper bending can be done with annealing the aluminum first although it s not an ideal candidate for formed parts.

Aluminum is a common metal used for both industrial and non industrial applications.

The aluminum series ability to bend tends to decrease as you move down the list of tempers from annealed to t4 and t6.

When you are forming aluminum if the radius is sharp small in relation to the material thickness you will overwork the material making it harder more brittle and much more likely to fail.

If your project does not have any physical or structural demands and the aesthetics are not important then almost any aluminum grade will do the job.

Bending is one of the most common sheet metal fabrication operations.

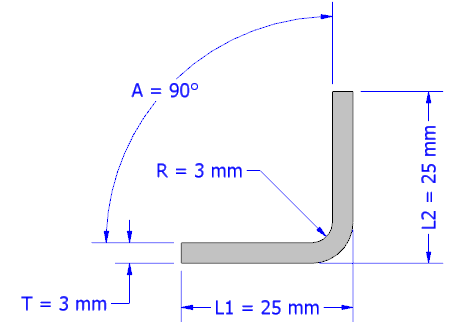

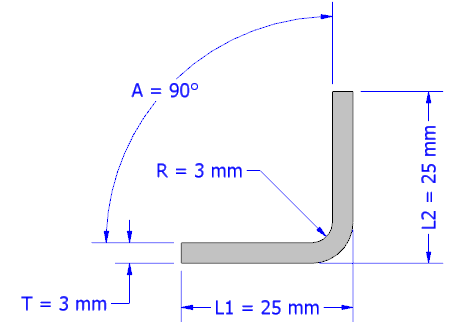

The minimum bend radius data shown in these charts is measured to the inside of the bend.

Just like all sheet metal aluminum work hardens during the forming process.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Miserable to bend cracking is very common and cold bending will always weaken the metal.

Material bend radii and minimum bend size charts please note.

This instructable shows how sheet aluminium may be cut using nothing but a knife and a metal straight edge.

Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

In high purity forms aluminum is soft and ductile.

Which aluminum alloy bends the best is a a common question customers want the answer to.