When voids nucleated due to the separation of the inclusions from the matrix the change in the material density in uniaxial tension was smaller than the change.

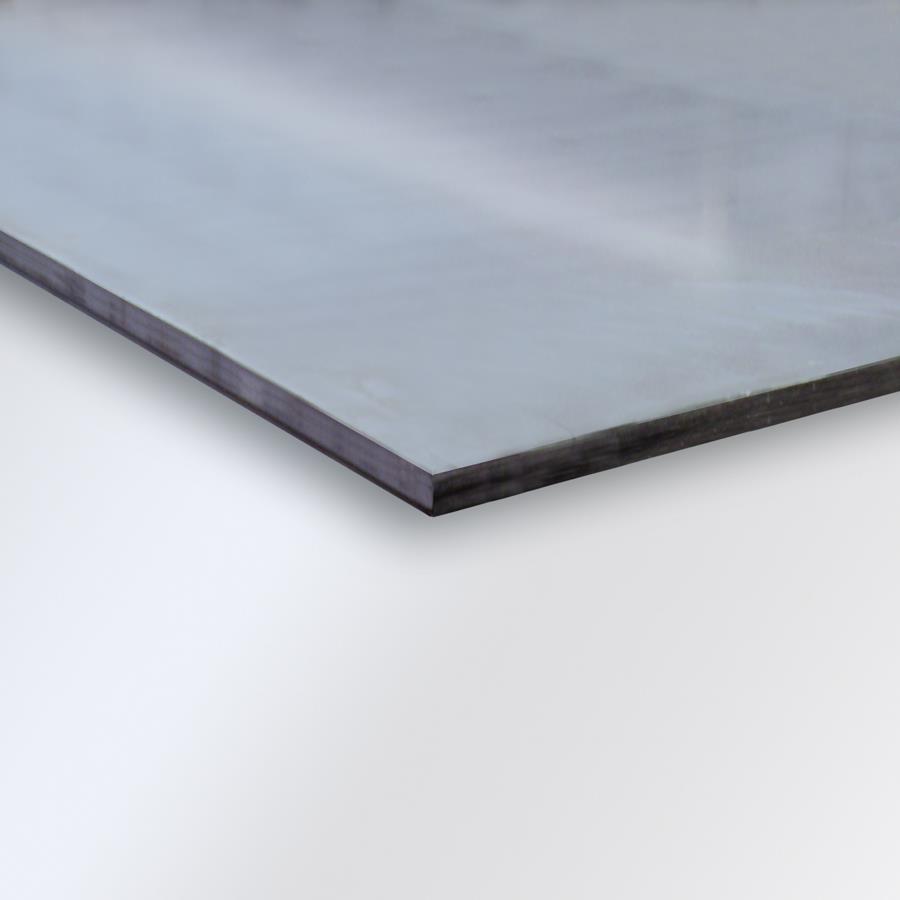

Aluminum killed steel sheet.

It refers to the adding aluminum to molten steel during the alloy process followed by the annealing and tempering the sheet undergoes.

Aluminium reacts with the dissolved gas to form aluminium oxide.

Aluminum killed akdq steel sheet is produced especially for fabricating into parts requiring severe forming or drawing operations too difficult for the drawing properties of commercial quality cold roll steel.

The aluminum oxide precipitates provide the additional benefit of pinning grain boundaries thereby preventing grain growth during heat treatments.

The specified thickness range captions noted above apply when sheet is specified to nominal thickness not minimum thickness.

For steels of the same grade a killed steel will be harder than rimmed steel.

Akdq stands for aluminum killed drawing quality.

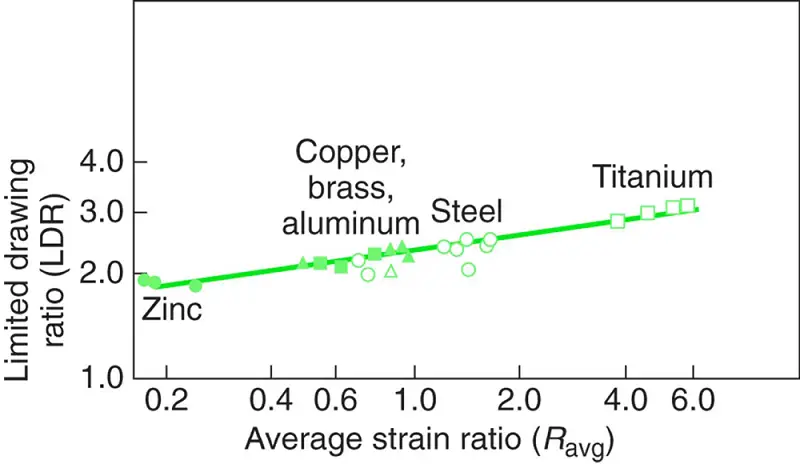

Schmitt and jalinier 1982 performed the uniaxial tension and the balanced biaxial tension of a sheet using aluminum killed steel electrolytic copper and 3003 aluminum alloy.

The end result is an a1008 steel sheet that can be oxy acetylene or tig welded with no gas bubbles forming.

The benefit of the aluminum killed process is uniformity and consistent performance because the addition of aluminum locks up the oxygen that normally occurs in the form of aluminum oxide.

Thickness is measured at any point across the width not less than 3 8 from a side edge.

Killed steel killed steel is deoxidized to such an extent that there is no gas evolution during solidification.

The benefit of the aluminum killed process is uniformity and consistent performance because the addition of aluminum locks up the oxygen that normally occurs in the form of aluminum oxide.

In some applications calcium silicide or other special strong deoxidizers are also used.

Schmitt and jalinier measured the material density using an electronic thermocontrolled balance and an electron microscope and modeled the growth of voids.

Aluminum killed steel is type of steel that has been entirely deoxidized by the addition of aluminum or any other additive in case of other killed steels other than aluminum prior to casting so that there is in reality no introduction of gas throughout solidification.

Aluminum together with ferroalloys of manganese and silicon is used for deoxidation.

In the internet can find materials which stated that carbon steel can be divided within two broad categories namly alluminium killed steel 0 03 si.

The end result is an a1008 steel sheet that can be oxy acetylene or tig welded with no gas bubbles forming.

Higher standards of production selection and processing of the steel result in greater ductility and uniformity.

As compared with sheets of commercial quality drawing quality aluminum killed sheet has a greater degree of ductility and is more consistent in performance using specially killed steel with aluminum as the deoxiclizing agent.