M d building products 1 ft.

Aluminum sheet metal hem.

We offer a variety of alloys including a large inventory of 6061 in a range of standard sizes and thicknesses.

Get it as soon as wed sep 16.

Industrial metal supply stocks a full line of aluminum sheet and plate.

Create a bend with acute angle tooling in the metal 30 is preferable but 45 will work for some circumstances.

Seams are commonly used in the food industry on canned goods on amusement park cars in metal roofing and in the automotive industry.

Magnetic brinell 95.

Steelworks 24 in x 48 in aluminum tread plate sheet metal.

Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects.

X 36 the md building products 36 in.

And while hems or seams reinforce a sheet metal edge their main purpose is to improve appearance by hiding burrs and rough edges on metal back splashes and other sheet metal installations.

Item 241558 model 11256.

20 pieces metal hemming clips sewing clips 3 inch stainless steel sewing crimping clip with measurement ruler quilting craft supplies for wonder clips.

Set your store to see local.

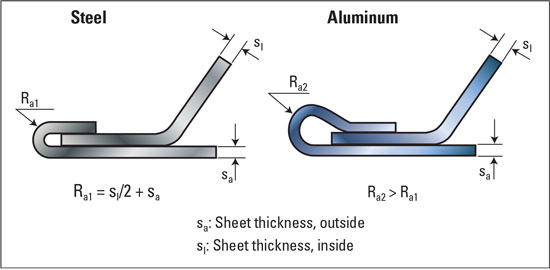

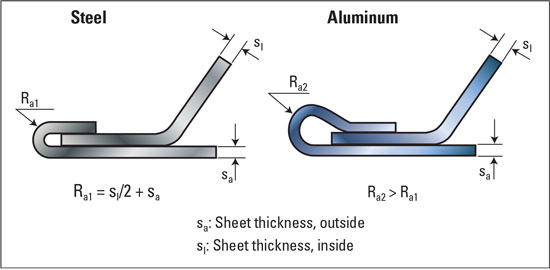

Hemming is the process in which the edge is rolled flush to itself while a seam joins the edges of two materials.

Your 1 source for aluminum sheet metal.

4 0 out of 5 stars 38.

Midwest seamer 15 inch straight sheet metal bender with aluminum blades kush n power comfort grip handle mwt s15.

When working with a brake press hems are always created in a two step process.

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself.

The sheet features a union jack style perforated design.

Hemming is a metalworking process where a sheet metal edge is mechanically bent to fit an uneven surface or simply roll over onto itself.

C1008 1010 hr steel sheet astm a1011 a569 hot rolled steel sheets are the most economical steel sheets available for a wide variety of applications hr steel sheets are easy to weld form and drill and has a slight grainy surface.

Diamond tred aluminum sheet heavy weight model 57575 13 49 13 49.

The md building products 36 in.

In sheet metal hemming means to fold the metal back on itself.

Hems are commonly used to reinforce an edge hide burrs and rough edges and improve appearance.

98 of products ordered ship from stock and deliver same or next day.

Popular uses for hr steel sheet include.